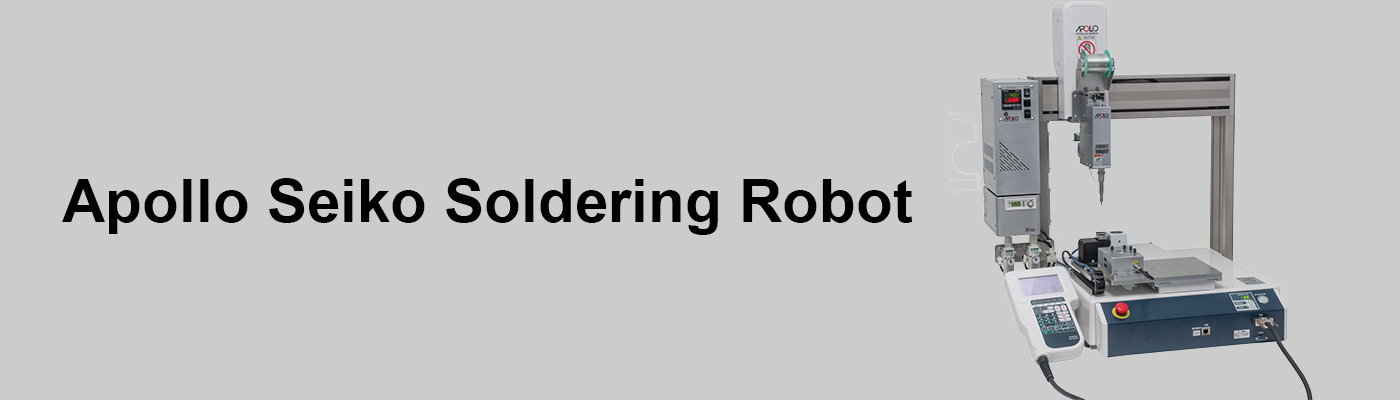

Apollo Seiko Soldering Robot Dealer, Supplier in Chennai | Flextech Automation

Apollo Seiko Soldering Robot Dealer, Supplier in Chennai – We’ve been committed advanced Apollo Seiko Soldering Robot solutions from Flextech Automation

Apollo Seiko Soldering Robot Dealer and Supplier in Chennai – Absolutely! Soldering robots are automated systems that are specifically designed to perform soldering operations in an accurate and efficient manner. They are widely utilized in electronics manufacturing processes, where precision and consistency are crucial for soldering components onto printed circuit boards (PCBs). By using soldering robots, companies can achieve higher levels of accuracy, improve production efficiency and ensure consistent soldering results.

Our Apollo Seiko Soldering robots are equipped with advanced features such as vision systems for component recognition and control mechanisms for precise soldering.

End-to-end Services for Apollo Seiko Soldering Robot in Chennai

The most contemporary advancements in base operational function, increased usability and durability. Primary innovations in technology include advanced temperature settings allowing temperature to be adjusted for each individual point. A new approach function allows for reduction in cycle time and makes programming / set-up much simpler. It also features an automatic sleep mode which significantly extends tip life.

Best Apollo Seiko soldering Solutions from us

Our Flextech Automation – This is Apollo Seiko soldering robot new all-in-one selective flow system. It is the perfect solution for a high-mix, low-volume environment. The machine is capable of pre-fluxing and pre-heating. Maintenance has never been easier with a built-in solder feeder and automated nozzle cleaning system.

The machine’s advanced vision system calibrates any application shift prior to fluxing/ soldering. It also has auto flow height adjustment by a touch probe. Additional features include auto-temp adjustments, multi-lingual support, and much more!

Key Features of Soldering Robots:

- Soldering robots are equipped with precise control systems, ensuring accurate application of solder to specific locations on a PCB. This precision is crucial for the reliability and functionality of electronic devices.

- These robots are often versatile and can handle various soldering tasks, such as through-hole soldering, surface mount device (SMD) soldering, and selective soldering. They can adapt to different board sizes and configurations.

- Soldering robots operate autonomously once programmed, reducing the need for manual labor in repetitive soldering tasks. This can lead to increased production efficiency and consistency.

- Users can program soldering robots to follow specific paths and soldering profiles. This flexibility allows for customization based on the requirements of different soldering applications.

- Soldering robots typically have precise temperature control mechanisms to ensure that the soldering iron or nozzle reaches and maintains the correct temperature for optimal soldering.

- Some soldering robots may incorporate vision systems for enhanced accuracy. These systems can identify soldering points on a PCB, correct for slight misalignments, and ensure proper solder placement.

Soldering robots, including those from Apollo Seiko, play a vital role in modern electronics manufacturing by offering precise and automated solutions for soldering processes. They contribute to improved efficiency, consistency, and overall quality in the production of electronic assemblies. For specific details about the Apollo Seiko Soldering Robot, I recommend checking the latest product documentation, contacting the manufacturer, or visiting their official website for the most accurate and up-to-date information.

For More Visit Google maps